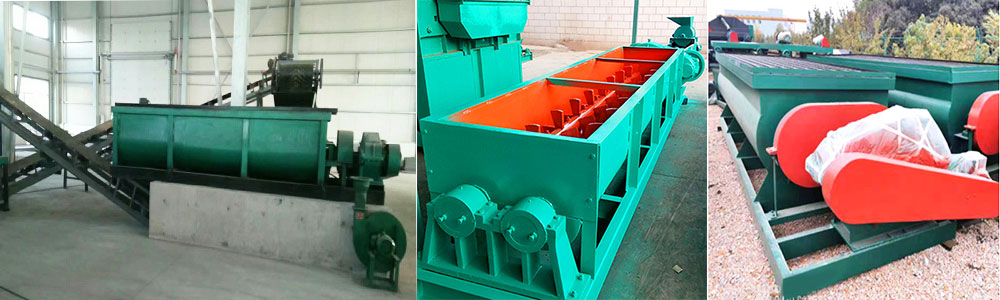

Twin shaft mixer is a new generation mixing equipment developed by our company. It can send eligible fine powder material after fertilizer screening and other auxiliary materials into equipment for mixing evenly and supply it to granulation process. Double shaft mixer has high mixing degree.less fertilizer residue, suitable for mixing more than two kinds of fertilizers,additive premixes, compound feeds, concentrated feeds, additive premixes etc.

Product Introduction:

Twin shaft mixer is a new generation mixing equipment developed by our company. It can send eligible fine powder material after fertilizer screening and other auxiliary materials into equipment for mixing evenly and supply it to granulation process. Double shaft mixer has high mixing degree.less fertilizer residue, suitable for mixing more than two kinds of fertilizers,additive premixes, compound feeds, concentrated feeds, additive premixes etc.

Product Feature:

※ Materials are fully mixed, thus improve mixing uniformity.

※ Fertilizer mixer adopt novel rotor structure, which effectively reduce residual amount of materials.

※ Special rotor design of fertilizer blender can also crush larger materials.

※ Overall structure is more reasonable, beautiful appearance, operation and maintenance are convenient.

Structure Overview:

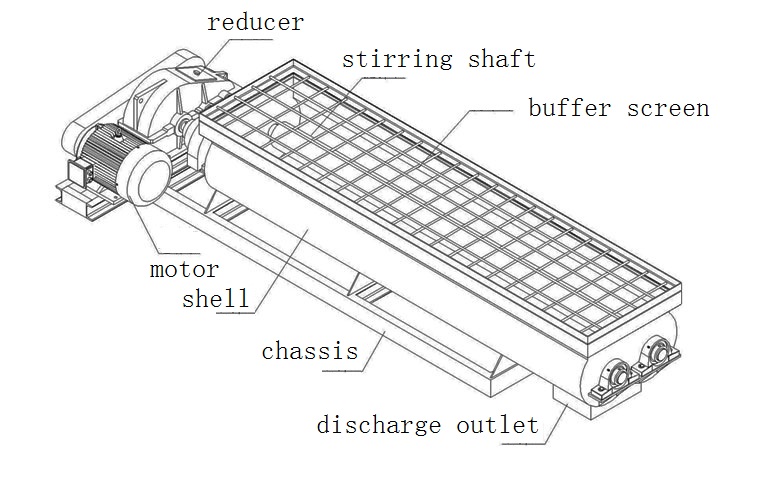

Twin shaft mixer is mainly composed of casing, screw shaft assembly, driving device, piping, cover plate, chain cover and other components. Specific structural performance characteristics are as follows:

1. The shell is mainly composed of plate and section steel, which is welded and formed in manufacturing plant, and assembled with other components,it is the support of twin shaft mixer. Casing is tightly sealed, there will be no flying ash or ash leakage.

2. Screw shaft assembly is main component of twin shaft mixer. Its components mainly include left and right helical shaft, bearing seat, bearing sleeve, bearing cap, gear, sprocket, oil cup, blade and other components. Material of the double shaft mixer blade is made of composite ceramics that wear-resistant and not easy to adhibit ash. The design of blade structure is reasonable and simple, easy to replace after wear and tear, longer service life.

3. Piping for adding water and adjusting humidity is mainly composed of connecting pipe, joint and nozzle. The nozzle is stainless steel atomizing cone nozzle, which are arranged above inside of mixer shell and arranged axially along direction of screw axis, form a water curtain to facilitate humidification and material mixing. The nozzle structure is simple, easy to replace, stainless steel, anti-corrosion and durable. Moisture content of wet ash can be adjusted by operating manual regulating valve on water supply pipeline.

4. Covers mainly include left cover, middle cover, right cover, hole cover and inspection hole cover, etc. There are six inspection holes on both sides of mixer fertilizer to facilitate operator's usual inspection and maintenance.

Working Principle:

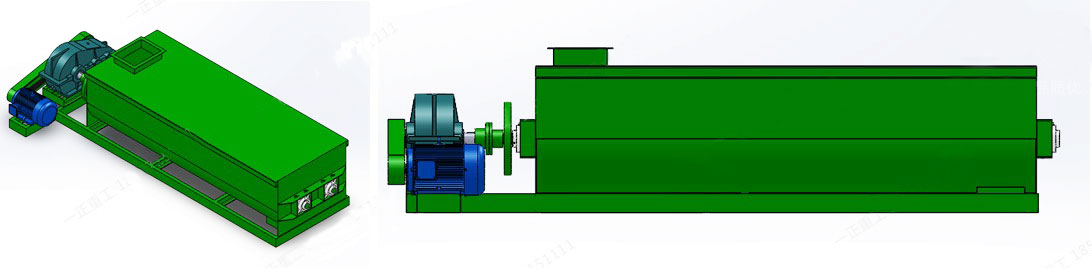

Double shaft mixer use synchronous rotation of two symmetrical helical shafts to stir and add water while conveying dry powdery materials, so as to evenly humidify dry ash and powdery materials,humidified materials will not emit dry or ooze out. Purpose of water droplets is to facilitate transportation of humidified ash by truck or transfer to other conveying equipment.

Barrel of fertilizer blender is equipped with paddles that rotate in opposite direction. Paddles form a certain angle to stir materials in axial and radial direction, so that materials can be mixed quickly and evenly. The motor drive to reducer through belt to make shaft rotation. Speed of shaft and paddle structure will weaken gravity of material. With the lack of gravity, differences in particle size and specific gravity of each material will be ignored during mixing process. Continuous material entry and exit is faster and more efficient. Even if there are differences in specific gravity and particle size of materials, a good mixing effect can be achieved under rapid and violent tumbling and throwing of staggered mixing blades.

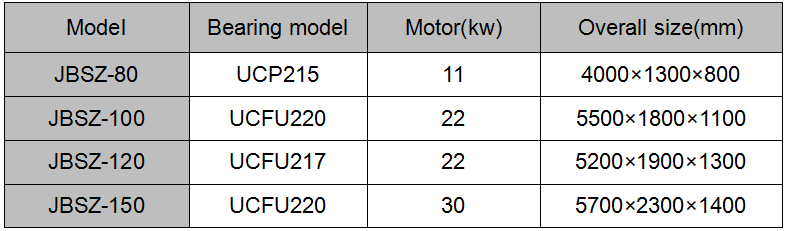

Technical Parameters:

Henan Lofty Fertilizer Machinery Co., Ltd. was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

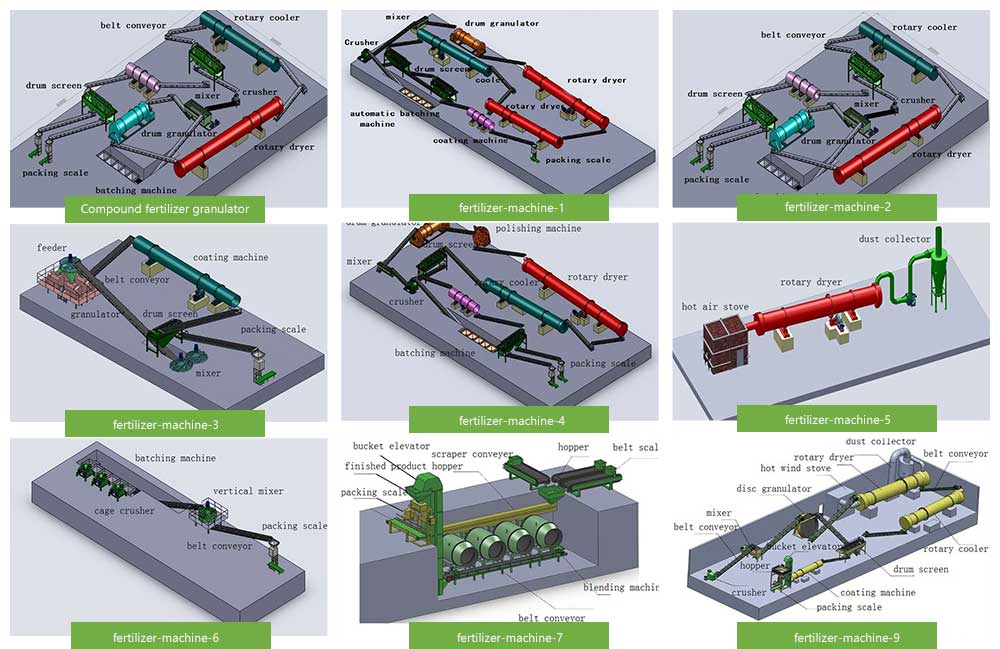

Main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure. We obtained 13 national utility model patent certificates, passed ISO9001 quality system certification and environmental management system certification; won honors such as "Contract-honoring and Promise-keeping Demonstration Enterprise", "AAA-Level Integrity Enterprise", "3.15 Product Quality Trustworthy Unit" and so on.

International Cooperation

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Henan Lofty Fertilizer Equipment Co., Ltd. has always been market-oriented, seeks development by innovation, strives for survival by quality, and takes perfect after-sales service. After more than 20 years of continuous development and innovation, it has gradually moved towards scientific, institutionalized, standardized management track. Warmly welcome people all over the world to visit, guide and negotiate business!

Staff Activity

Q: What is your company hot product?

A: Our main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure.

Q: Are you a factory?

A: Yes,we are direct source factory,was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Q: Whether can you provide customized product?

A: Yes, we focus on customer needs, commit to creating value for customers, provide personalized designs and products according to the actual situation.

Q: I am the new beginner of fertilizer equipment. How can i choose the most suitable machine?

A: Please let us know your raw materials type, water content, capacity (t / h) and final particle size, our engineer will design plan and make official quotation.

Q: How long is the production period of fertilizer equipment?

A: For single set fertilizer equipment, delivery time is 7 days; for complete production line, delivery time is 35 working days.

Q: How to guarantee your machine quality?

A: 100% new before leave our factory, we guarantee our machine 14 months after shipment date.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: What is your payment method?

A: 30% prepayment to confirm order after sign PI or SC,the rest 70% should be paid before delivery.We also accept L/C.

Q: Do you provide installation and operation training?

Yes.If you required,we can dispatch engineer to the site for guiding machine installation, At the same time train skilled workers how to operate the machine. Installer's salary is calculated separately.

Contact: Sophia

Phone: +86 13619848687

E-mail: [email protected]

Whatsapp:+86 13619848687

Add: NO.85 Jinshui East Road, Zhengzhou Area (zhengdong) of Henan Piolt Free Trade Zone,China.

We chat