Flat die granulator is suitable for granulation of rough fermented organic fertilizer. Mainly suitable for coarse fiber granulation, such as: wood chips, rice husks, cotton stalks, cottonseed husks, weeds and other crop straws, domestic garbage, waste plastics and factory waste, materials granulation, briquetting, rod making which with low bonding rate and difficult to shape, also suitable for low-temperature granulation of biological bacterial fertilizer, organic fertilizer, compound fertilizer etc.

Product Introduction:

Flat die granulator is suitable for granulation of rough fermented organic fertilizer. Mainly suitable for coarse fiber granulation, such as: wood chips, rice husks, cotton stalks, cottonseed husks, weeds and other crop straws, domestic garbage, waste plastics and factory waste, materials granulation, briquetting, rod making which with low bonding rate and difficult to shape, also suitable for low-temperature granulation of biological bacterial fertilizer, organic fertilizer, compound fertilizer etc.

Product Feature:

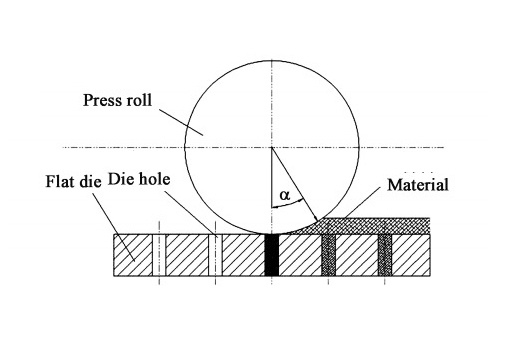

※ Flat die extrusion granulator adopt pressure roller, and linear speed of both ends is consistent with mold plate inner and outer rings. There is no dislocation friction between wheel and mold, which reduce resistance and kinetic energy loss, prolong service life of mold, reduce production costs.

※ Pressing rollers are evenly distributed, operation is stable. At the same time, pressing area is increased, production efficiency is improved.

※ With the screw center pressure regulating structure, gap between molds varies with the size, suitable for different material to ensure pressing effect.

※ Wide adaptability of raw materials, especially suitable for organic matter.

※ Fermented organic matter does not need to be dried, moisture content of raw material can be 20%-40%.

※ Particle composition is uniform, shape is neat, pore size of particle size can be divided into: Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Buyers can choose according to production need when ordering.

※ Surface of granular material processed by roller press granulator is smooth and clean, hardness is moderate, temperature rise is low during processing process, nutrients inside can be well maintained.

※ Due to low moisture content of the particles, it is easy to store, can keep original shape for a long time in water, which greatly improves utilization rate of materials.

※ Utilizing the characteristic that organic particles can be embedded and grow up under corresponding action, no binder is needed during granulation.

※ Granules are firm and can be sieved after granulation to reduce drying energy consumption.

Structure Overview:

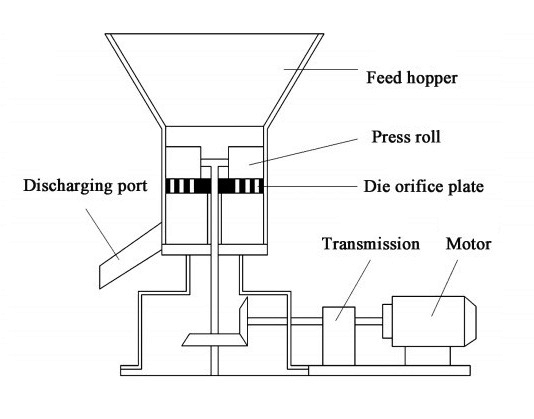

Flat die press granulator is mainly composed of feed hopper, pressing roller, die orifice plate, gearbox, motor and machine frame.

Working Principle:

Flat die extrusion granulator is based on motor as power and circular motion of mechanical. Under action of friction, pressure roller rotate, temperature is generated between pressure roller and granules. The powdery material is gelatinized after high temperature and extruded from die hole under extrusion action of pressure roller, then pellets are sent out of machine through throwing tray, finally length of pellet is controlled by cutter.

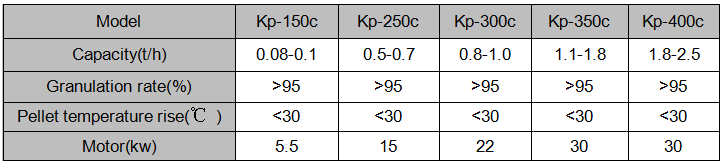

Technical Parameters:

Henan Lofty Fertilizer Machinery Co., Ltd. was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

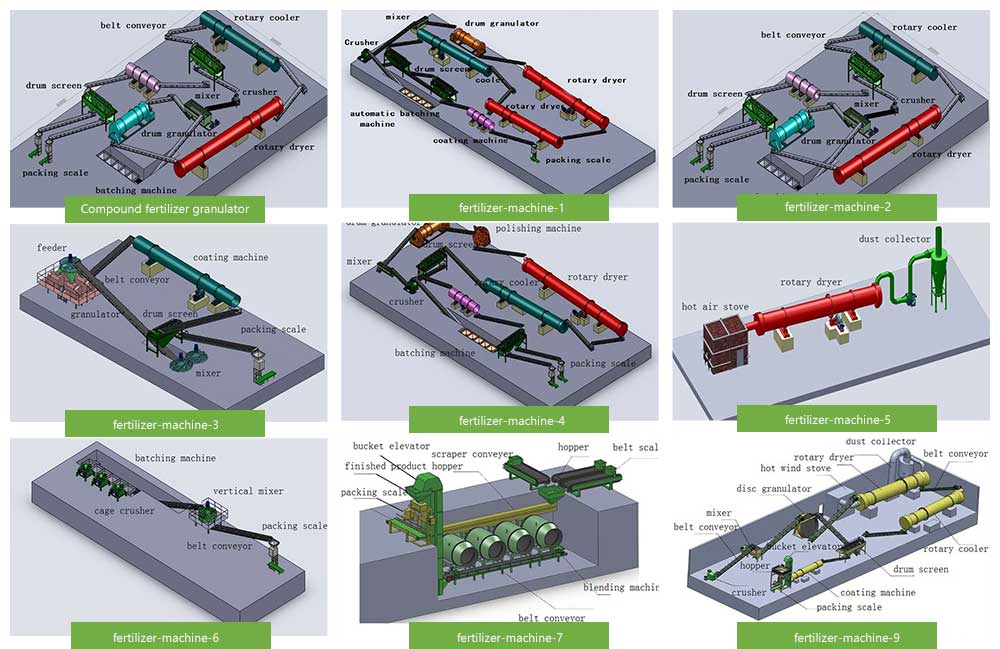

Main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure. We obtained 13 national utility model patent certificates, passed ISO9001 quality system certification and environmental management system certification; won honors such as "Contract-honoring and Promise-keeping Demonstration Enterprise", "AAA-Level Integrity Enterprise", "3.15 Product Quality Trustworthy Unit" and so on.

International Cooperation

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Henan Lofty Fertilizer Equipment Co., Ltd. has always been market-oriented, seeks development by innovation, strives for survival by quality, and takes perfect after-sales service. After more than 20 years of continuous development and innovation, it has gradually moved towards scientific, institutionalized, standardized management track. Warmly welcome people all over the world to visit, guide and negotiate business!

Staff Activity

Q: What is your company hot product?

A: Our main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure.

Q: Are you a factory?

A: Yes,we are direct source factory,was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Q: Whether can you provide customized product?

A: Yes, we focus on customer needs, commit to creating value for customers, provide personalized designs and products according to the actual situation.

Q: I am the new beginner of fertilizer equipment. How can i choose the most suitable machine?

A: Please let us know your raw materials type, water content, capacity (t / h) and final particle size, our engineer will design plan and make official quotation.

Q: How long is the production period of fertilizer equipment?

A: For single set fertilizer equipment, delivery time is 7 days; for complete production line, delivery time is 35 working days.

Q: How to guarantee your machine quality?

A: 100% new before leave our factory, we guarantee our machine 14 months after shipment date.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: What is your payment method?

A: 30% prepayment to confirm order after sign PI or SC,the rest 70% should be paid before delivery.We also accept L/C.

Q: Do you provide installation and operation training?

Yes.If you required,we can dispatch engineer to the site for guiding machine installation, At the same time train skilled workers how to operate the machine. Installer's salary is calculated separately.

Contact: Sophia

Phone: +86 13619848687

E-mail: [email protected]

Whatsapp:+86 13619848687

Add: NO.85 Jinshui East Road, Zhengzhou Area (zhengdong) of Henan Piolt Free Trade Zone,China.

We chat