Round polishing machine is suitable for rounding particles of organic fertilizer and compound fertilizer that use chicken manure and other livestock manure as main raw material; rounding bio-organic fertilizer particles that use grass ash, lignite, organic fertilizer sludge, straw and other raw materials; rounding cake fertilizer particles that use bean cake as main raw material; rounding various fertilizer and feed particles.

Product Introduction:

Fertilizer polishing machine can beautify all granular fertilizers. The granular fertilizers produced by extrusion granulator or disc granulator will be uniform in size, accurate in roundness, bright and smooth after rounding by disc polisher. High strength, pelleting rate is up to 98%, low pellet return rate. So it can reduce energy consumption and increase production. Produced granules have low water content and easy to dry. At the same time, it can also produce feed pellets, which is an ideal equipment for making organic fertilizer pellets.

Scope Of Application

Round polishing machine is suitable for rounding particles of organic fertilizer and compound fertilizer that use chicken manure and other livestock manure as main raw material; rounding bio-organic fertilizer particles that use grass ash, lignite, organic fertilizer sludge, straw and other raw materials; rounding cake fertilizer particles that use bean cake as main raw material; rounding various fertilizer and feed particles.

Product Feature:

※ Organic fertilizer round polisher can effectively improve appearance quality of particles and can be flexibly configured according to product needs during production process. It is used together with granulator to make up series of shortcomings such as uneven particle size and phase difference during mass production.

※ This machine is composed of two or three throwing cylinders arranged in sequence. Materials are thrown round several times, finished product is discharged from outlet. Finished particles are consistent in size, round and smooth, yield is up to 98%. A small amount of fertilizer powder falls from gap on edge of disc polishing machine and then discharged along waste port.

※ Beautiful appearance, simple structure and working principle. Reliable installation, small size, light weight, easy operation and maintenance.

※ Strong adaptability, able to work in various environments, it can maintain continuous operation for a long time, with low power consumption, electricity saving, low production cost and high economic benefits.

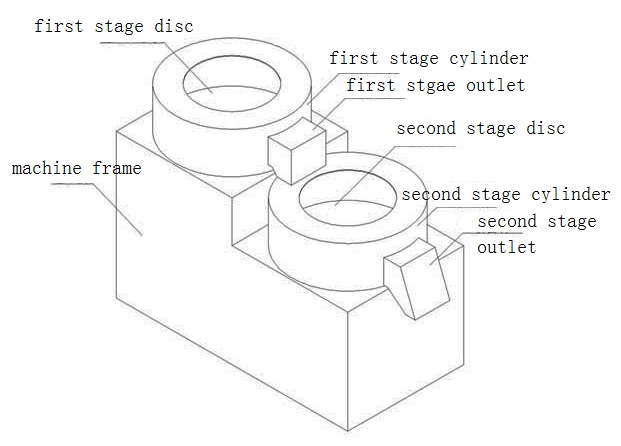

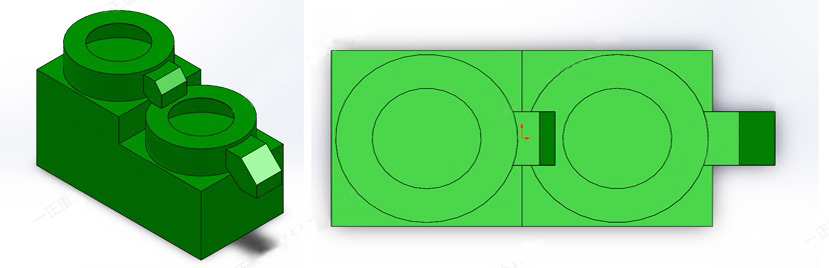

Structure Overview:

Organic fertilizer rounding machine is a multi-layer continuous particle polishing and shaping equipment. A big cylinder is fixed on top of frame, upper end of it has an cover. There is a large turntable at bottom of large cylinder, the vertical shaft is connected with frame by two bearings,lower end of vertical shaft is connected with output shaft of motor through reducer or pulley, upper part of the vertical shaft extends into big cylinder, fixedly connected to large turntable through flange. Outer edge of turntable is in sliding contact with inner wall of large cylinder. There is a discharging chute on one side of big cylinder and under large turntable. After raw material particles enter rounding machine and are rounded, they enter next rounding machine or receiver through discharge port on one side, powder is discharged from discharge chute under the large turntable.

Working Principle:

Columnar granular material rotates with throwing disc under action of friction. Throwing cylinder is stationary. In this way, the columnar material in throwing cylinder reciprocates turn round along edge of throwing disc and wall of throwing cylinder under action of centrifugal force in a twisted shape. Continuous feeding reach discharge height of throwing disc discharge port, and automatically enter next throwing disc.

The material coming out of throwing disc has changed from columnar to irregular round granular, then do same movement by next throwing disc. It become uniform and bright round particle organic fertilizer (moisture content is high) after coming out of multi-stage throwing discs. Finally transport to drying section.

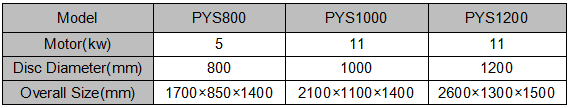

Technical Parameters:

Henan Lofty Fertilizer Machinery Co., Ltd. was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

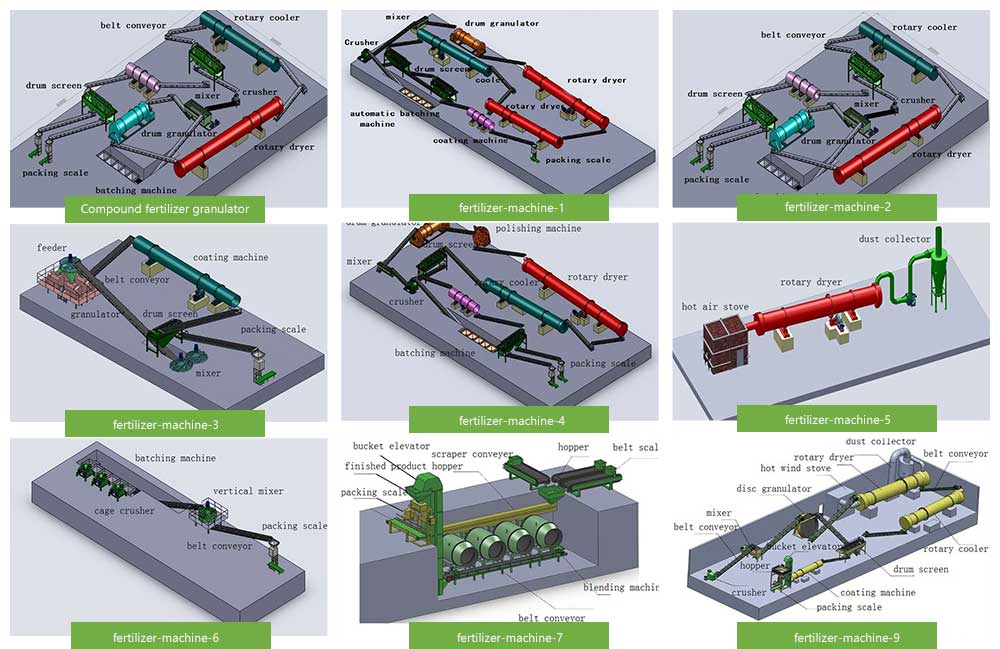

Main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure. We obtained 13 national utility model patent certificates, passed ISO9001 quality system certification and environmental management system certification; won honors such as "Contract-honoring and Promise-keeping Demonstration Enterprise", "AAA-Level Integrity Enterprise", "3.15 Product Quality Trustworthy Unit" and so on.

International Cooperation

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Henan Lofty Fertilizer Equipment Co., Ltd. has always been market-oriented, seeks development by innovation, strives for survival by quality, and takes perfect after-sales service. After more than 20 years of continuous development and innovation, it has gradually moved towards scientific, institutionalized, standardized management track. Warmly welcome people all over the world to visit, guide and negotiate business!

Staff Activity

Q: What is your company hot product?

A: Our main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure.

Q: Are you a factory?

A: Yes,we are direct source factory,was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Q: Whether can you provide customized product?

A: Yes, we focus on customer needs, commit to creating value for customers, provide personalized designs and products according to the actual situation.

Q: I am the new beginner of fertilizer equipment. How can i choose the most suitable machine?

A: Please let us know your raw materials type, water content, capacity (t / h) and final particle size, our engineer will design plan and make official quotation.

Q: How long is the production period of fertilizer equipment?

A: For single set fertilizer equipment, delivery time is 7 days; for complete production line, delivery time is 35 working days.

Q: How to guarantee your machine quality?

A: 100% new before leave our factory, we guarantee our machine 14 months after shipment date.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: What is your payment method?

A: 30% prepayment to confirm order after sign PI or SC,the rest 70% should be paid before delivery.We also accept L/C.

Q: Do you provide installation and operation training?

Yes.If you required,we can dispatch engineer to the site for guiding machine installation, At the same time train skilled workers how to operate the machine. Installer's salary is calculated separately.

Contact: Sophia

Phone: +86 13619848687

E-mail: [email protected]

Whatsapp:+86 13619848687

Add: NO.85 Jinshui East Road, Zhengzhou Area (zhengdong) of Henan Piolt Free Trade Zone,China.

We chat