Belt conveyor is also named cleated belt conveyor or flat belt conveyor. It is a conveying equipment that participate in conveying of materials in whole organic fertilizer production line. It is an indispensable economical logistics conveying equipment to form rhythmic assembly line.

Product Introduction:

Belt conveyor is also named cleated belt conveyor or flat belt conveyor. It is a conveying equipment that participate in conveying of materials in whole organic fertilizer production line. It is an indispensable economical logistics conveying equipment to form rhythmic assembly line.

Idler roller belt conveyor can be divided into heavy belt conveyor such as mining belt conveyor and light belt conveyor such as those used in electronic plastics, food light industry, chemical and pharmaceutical industries according to conveying capacity, It is suitable for conveying low-abrasive materials and bagged materials with density <1.67 t/m3 and easy to dig out, such as coal, gravel, sand, cement, fertilizer, grain etc. Temperature of transport material is < 60°C. Its length and assembly form can be determined according to user requirements. Transmission can be electric drum, or driving device with driving frame.

Product Feature:

※ Large conveying capacity, simple structure, convenient maintenance, low cost and strong versatility.

※ Low power consumption, reduce production cost.

※ It is convenient to implement programmed control and automatic operation.

※ Use continuous or intermittent motion of conveyor belt to transport goods <100kg or powdery and granular items. It runs at high speed, stable, low noise, and can realize up and down slope transmission.

※ Transmission line has strong adaptability and can be adjusted, belt length can be determined according to needs. Shortest is a few meters, longest is >10km.

※ Installation position of belt conveyor is flexible, it can be installed in a small tunnel, also be erected above chaotic and dangerous areas on the ground.

※ It is very flexible to receive materials from one or more points, also can discharge materials to multiple points or several sections.

Structure Overview:

Dirt belt conveyor is a friction driven machine that transport material in a continuous manner. It is mainly composed of frame, conveyor belt, idler roller, roller, tensioning device, transmission device and so on.

Working Principle:

Belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly sleeved on them. Pulley that drive conveyor belt to rotate is called drive drum (drive pulley), the other pulley that only change movement direction of conveyor belt is called redirection drum. The drive drum is driven by motor through reducer, conveyor belt is dragged by friction between drive drum and conveyor belt. Drive drum are generally installed on discharge end in order to increase traction and easy to drag. Raw material is fed from feeding end, falls on rotating conveyor belt, transported to discharge end by friction of conveyor belt.

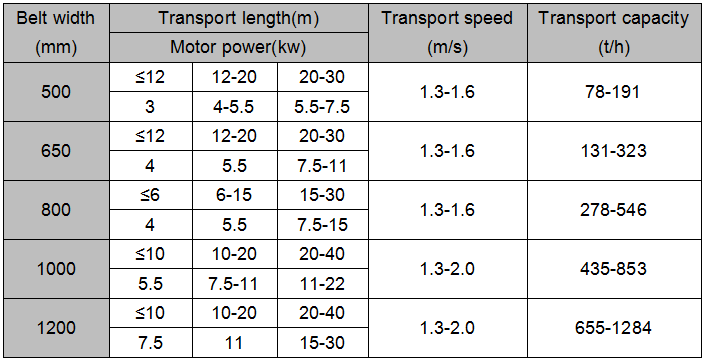

Technical Parameters:

Henan Lofty Fertilizer Machinery Co., Ltd. was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

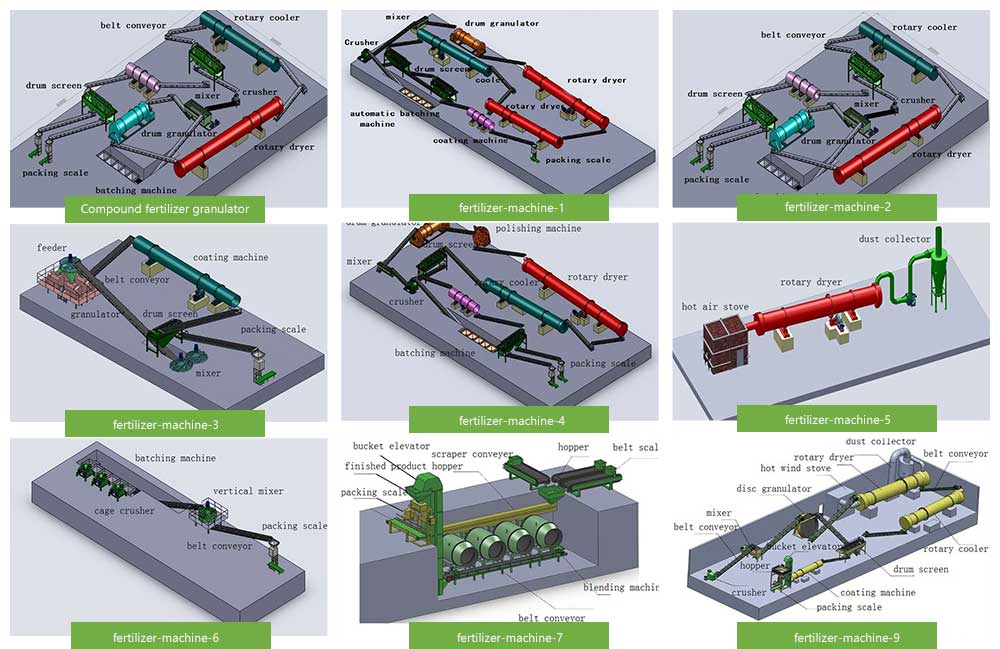

Main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure. We obtained 13 national utility model patent certificates, passed ISO9001 quality system certification and environmental management system certification; won honors such as "Contract-honoring and Promise-keeping Demonstration Enterprise", "AAA-Level Integrity Enterprise", "3.15 Product Quality Trustworthy Unit" and so on.

International Cooperation

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Henan Lofty Fertilizer Equipment Co., Ltd. has always been market-oriented, seeks development by innovation, strives for survival by quality, and takes perfect after-sales service. After more than 20 years of continuous development and innovation, it has gradually moved towards scientific, institutionalized, standardized management track. Warmly welcome people all over the world to visit, guide and negotiate business!

Staff Activity

Q: What is your company hot product?

A: Our main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure.

Q: Are you a factory?

A: Yes,we are direct source factory,was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Q: Whether can you provide customized product?

A: Yes, we focus on customer needs, commit to creating value for customers, provide personalized designs and products according to the actual situation.

Q: I am the new beginner of fertilizer equipment. How can i choose the most suitable machine?

A: Please let us know your raw materials type, water content, capacity (t / h) and final particle size, our engineer will design plan and make official quotation.

Q: How long is the production period of fertilizer equipment?

A: For single set fertilizer equipment, delivery time is 7 days; for complete production line, delivery time is 35 working days.

Q: How to guarantee your machine quality?

A: 100% new before leave our factory, we guarantee our machine 14 months after shipment date.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: What is your payment method?

A: 30% prepayment to confirm order after sign PI or SC,the rest 70% should be paid before delivery.We also accept L/C.

Q: Do you provide installation and operation training?

Yes.If you required,we can dispatch engineer to the site for guiding machine installation, At the same time train skilled workers how to operate the machine. Installer's salary is calculated separately.

Contact: Sophia

Phone: +86 13619848687

E-mail: [email protected]

Whatsapp:+86 13619848687

Add: NO.85 Jinshui East Road, Zhengzhou Area (zhengdong) of Henan Piolt Free Trade Zone,China.

We chat