BB fertilizer mixer, also known as blended horizontal drum mixer, is made by mixing single fertilizer (or multi-component fertilizer) in a certain proportion. Characteristic of BB liquid fertilizer mixer is that the ratio of nitrogen, phosphorus, potassium and trace elements is easy to adjust, can produce various specifications of special fertilizer according to user need, which is more suitable for need of soil testing and formula fertilization.

Product Introduction:

BB fertilizer mixer, also known as blended horizontal drum mixer, is made by mixing single fertilizer (or multi-component fertilizer) in a certain proportion. Characteristic of BB liquid fertilizer mixer is that the ratio of nitrogen, phosphorus, potassium and trace elements is easy to adjust, can produce various specifications of special fertilizer according to user need, which is more suitable for need of soil testing and formula fertilization.

BB fertiliser mixer overcome the phenomenon of chromatography or shunting of mixture caused by different specific gravity and particle size of raw materials, improve batching accuracy. It solve impact on system caused by factors such as material characteristic, mechanical vibration, air pressure, voltage fluctuations, cold weather etc. It has characteristics of high precision, fast speed,long service life. It is an ideal choice for BB fertilizer (blend fertilizer) production line.

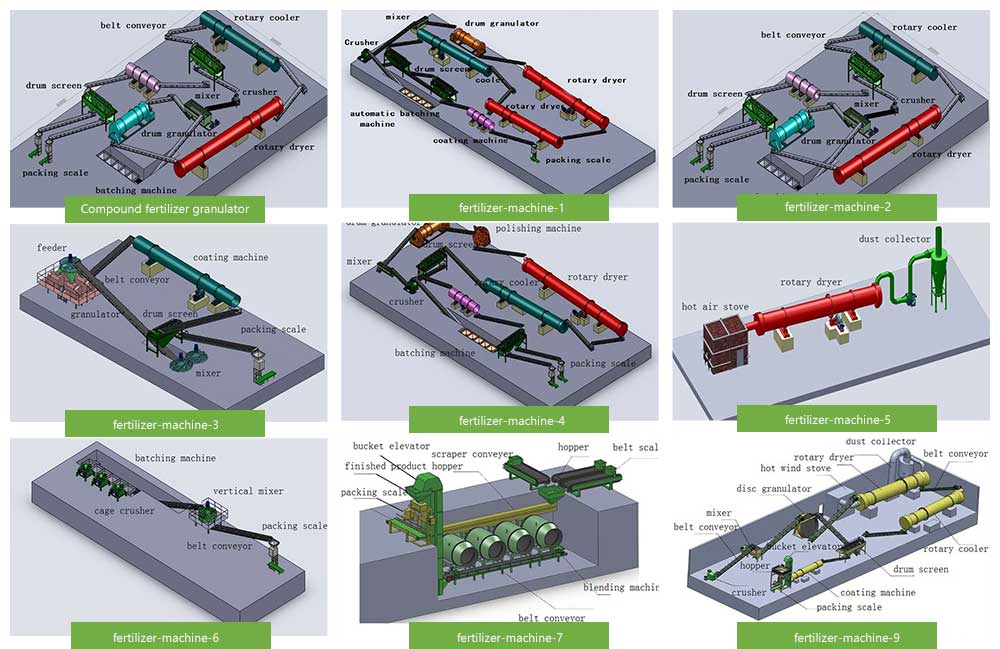

Complete set of BB fertilizer blending equipment is mainly composed of following equipment: storage silo, feeder, weighing scale, mixer, large-inclination Belt conveyor, quantitative packaging machine, automatic sewing machine, finished product transfer belt conveyor, computer control system.

Process is as follow: storage system→feeding system→metering system→conveying and lifting system→stirring and mixing→automatic packaging and sewing→finished product belt transfer→computer control system.

Product Feature:

※ It has high stirring efficiency and occupy small area (25-50m2). Spiral blades are made of high wear-resistant special alloy.

※ Driven by reducer, rotation is stable with low noise.

※ Single-shaft mixer feed from top and discharge from bottom, with reasonable structure.

※ Sealing between joint surface is tight, operation is stable.

※ Low power consumption (power of whole set of equipment is <10 kw/h).

※ Host machine is made of industrial grade stainless steel, control system use high-performance industrial computer, which is suitable for various harsh on-site environments.

※ Using two-stage shockproof treatment and multi-stage filtering technology, measurement is accurate and precision is high.

※ Automatically control high-speed communication interface 485 or 232, formula can be adjusted at any time, enterprise can change production formula according to different requirements of fertilizer sale.

※ Automatic mixing and packaging, uniform mixing, exquisite packaging, no separation of material during packaging process. Mixing range of 10-60kg can be adjusted arbitrarily to overcome segregation phenomenon of big batching in production and packaging process, thereby saving cost and consumption.

※ Actuator adopt pneumatic drive, big and small two-level feeding, independent measurement and cumulative measurement of various materials, production speed is fast.

※ Control system has automatic zero tracking, automatic tare weight removal, rough measurement, automatic drop compensation, automatic measurement and correction of overshoot and fault alarm.

Structure Overview:

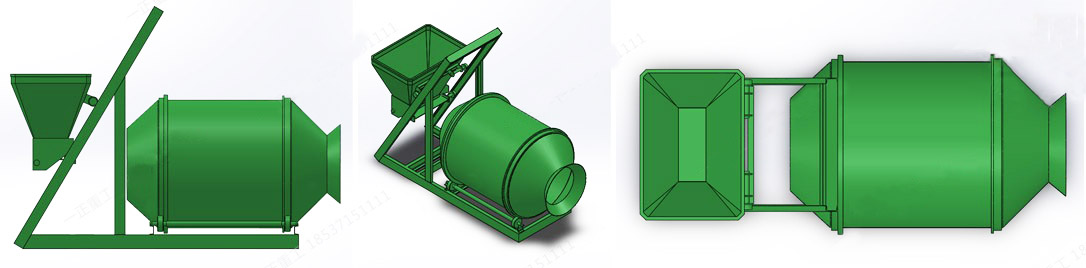

Horizontal batch mixer can be divided into three parts:

1. Frame part: all working parts of machine are fixed on frame. The frame of machine is welded by high-quality carbon steel plate and channel steel, has passed strict process requirements.

Transmission connection part: motor drive pulley, V-belt and reducer to drive, gear installed on reducer mesh with gears of machine body to drive barrel to work.

2.Working part of barrel: barrel part of machine is made of high-quality carbon steel plate through special processing. Inner wall of barrel is equipped with special spiral stirring blade. While barrel is working, material enters from feed inlet, material is evenly stirred under turning of special spiral stirring blade, which avoid shunt phenomenon during flow process because of difference in specific gravity and particle size of material.

3. Feeding part of climbing bucket:feeding part of climbing bucket is designed with special technology. Guide rails of climbing bucket are all made of high-quality channel steel, with reasonable angle design to make operation stable, overcome the problems of difficult feeding and lifting bucket easy to deviate caused by height restriction in the past.

Working Principle:

BB dry fertilizer mixer(blending mixer) adopt forward and reverse rotation, carry out material mixing and output through special inner screw mechanism and unique three-dimensional structure. This equipment is novel in design and strong in practicability. Feeding system does not store material, mixing system is mixed evenly, electronic control system, manual, automatic, composite settings are all features that other similar products do not have.

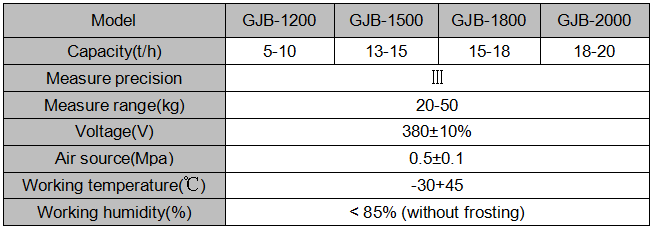

Technical Parameters:

Henan Lofty Fertilizer Machinery Co., Ltd. was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure. We obtained 13 national utility model patent certificates, passed ISO9001 quality system certification and environmental management system certification; won honors such as "Contract-honoring and Promise-keeping Demonstration Enterprise", "AAA-Level Integrity Enterprise", "3.15 Product Quality Trustworthy Unit" and so on.

International Cooperation

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Our company follows the concept of "service marketing" and cooperates with National Agricultural Technology Research Institute for many times, specializing in development of agricultural environmental protection technology and reducing waste for reuse. We have strong technical force, high-quality R&D, design and manufacturing teams. For a long time, we have been committed to the production of organic fertilizer production lines, compound fertilizer production lines and BB fertilizer production lines, providing customers with process design, equipment manufacturing, installation&commissioning etc one-stop services. Our equipment across the country and is exported to Southeast Asia, Africa, South America, European countries.

Henan Lofty Fertilizer Equipment Co., Ltd. has always been market-oriented, seeks development by innovation, strives for survival by quality, and takes perfect after-sales service. After more than 20 years of continuous development and innovation, it has gradually moved towards scientific, institutionalized, standardized management track. Warmly welcome people all over the world to visit, guide and negotiate business!

Staff Activity

Q: What is your company hot product?

A: Our main products include: organic fertilizer, compound fertilizer, BB fertilizer, blended fertilizer complete production line with capacity 10,000--200,000 tons/year, non-drying extrusion production line, high-humidity materials drying and fermentation equipment such as chicken manure.

Q: Are you a factory?

A: Yes,we are direct source factory,was established in 2001 year, located in Xingyang --- the hometown of machinery in Henan province, 15 kilometers from west of Zhengzhou.

Q: Whether can you provide customized product?

A: Yes, we focus on customer needs, commit to creating value for customers, provide personalized designs and products according to the actual situation.

Q: I am the new beginner of fertilizer equipment. How can i choose the most suitable machine?

A: Please let us know your raw materials type, water content, capacity (t / h) and final particle size, our engineer will design plan and make official quotation.

Q: How long is the production period of fertilizer equipment?

A: For single set fertilizer equipment, delivery time is 7 days; for complete production line, delivery time is 35 working days.

Q: How to guarantee your machine quality?

A: 100% new before leave our factory, we guarantee our machine 14 months after shipment date.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: Which type trade terms do you offer?

A: EXW/FOB/CFR/CIF/ are all accepted by us.

Q: What is your payment method?

A: 30% prepayment to confirm order after sign PI or SC,the rest 70% should be paid before delivery.We also accept L/C.

Q: Do you provide installation and operation training?

Yes.If you required,we can dispatch engineer to the site for guiding machine installation, At the same time train skilled workers how to operate the machine. Installer's salary is calculated separately.

Contact: Sophia

Phone: +86 13619848687

E-mail: [email protected]

Whatsapp:+86 13619848687

Add: NO.85 Jinshui East Road, Zhengzhou Area (zhengdong) of Henan Piolt Free Trade Zone,China.

We chat